Shaping Makes Beauty

Menu

Close

We also always explore the new yarn, new tech,new trends at the market .

Using our expansive list of global resources, we have access to the finest quality material and cutting-edge trend innovations for our products. Our strategic, global presence enables us to provide quality workmanship and on-time delivery for our partners.

Our company is an industry support company that focuses on providing ODM (Original Design Manufacturing) and OEM (Original Equipment Manufacturing) services to customers. We are committed to helping customers build their own brands and provide a full range of support and solutions. We have an experienced team with comprehensive technical knowledge and professional design capabilities. We can provide customized product design and manufacturing services according to customer needs and requirements. We have advanced production equipment and strict quality control processes to ensure that customers’ products can be delivered on time and meet high standards of quality requirements.

If you are looking for a reliable partner to help you build your brand, we would like to be your first choice. Whether it is ODM or OEM, we will do our best to provide you with the best service and support to help you successfully build your own brand.

In today’s market, consumers and businesses are becoming increasingly accustomed to customization. If you want your brand to be competitive, you will need to fully understand the needs of consumers. Customization is a feature that you can provide for customers to appreciate, and we are committed to helping customers promote their brand!

As you can design it, we can find the perfect crafts and techniques to realize it. Get your logo seen within your budget, beyond your expectation.You just need to send your artwork in AI/PSD File, then, confirm on the size of the logo and where to locate in the garment, and confirm on the type of logo.

A sewing line, also known as an assembly line or production line, is an essential component of the garment and textile manufacturing process. It is an efficient and organized system consisting of workstations arranged in sequence, each dedicated to a specific task in the sewing process.

A sewing line is designed to streamline the production process, minimize waste, and optimize productivity. It is typically composed of various workstations, such as cutting, sewing, punching, and precision finishing. Each workstation is equipped with specialized machines and tools to perform a specific task, ensuring accuracy and consistency in the final product.

A key advantage of a sewing line is its ability to divide the labor-intensive sewing process into smaller, more manageable tasks. This division of labor allows for specialization, where each worker can expertly perform the assigned task, thereby increasing efficiency and reducing production time. In addition, it enables better quality.

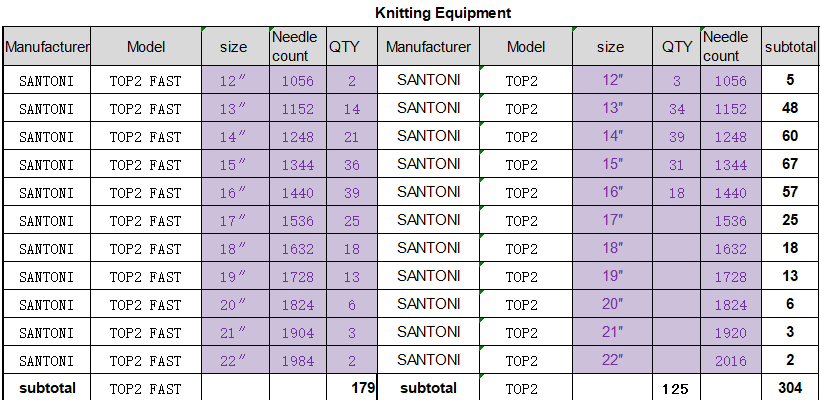

Santoni Knitting has rich experience and professional knowledge in knitting technology, and can provide various types of knitted products, including fabrics, socks, underwear, sportswear, etc. The company’s knitting machinery equipment adopts advanced technology and design, which can efficiently produce various complex knitting structures.

Santoni Knitting’s products are characterized by high quality, durability, and comfort. The company focuses on innovation and research and development, continuously launching new knitted products and technologies to meet market demand. In addition, the company also provides customized solutions to design and produce knitted products according to customer needs.

Santoni Knitting has a wide customer base worldwide, including fashion brands, sports brands, lingerie brands, and more. The company has won the trust and praise of customers with its excellent quality and service.

We have advanced technology and efficient production capacity to meet the needs of large-scale production. The equipment adopts high-quality materials and precision manufacturing technology to ensure stable and reliable product quality. At the same time, the equipment is equipped with advanced automation control systems, which improve production efficiency and product consistency. The equipment operation is simple and convenient, and the operators can operate proficiently after professional training, ensuring the smooth progress of the production process. Whether it is producing large quantities of orders or personalized customization, this device can meet the needs of customers.

We sincere hope to tight cooperate with you, To create mutual un-limit benefits in near future.

Strong and Rich experienced 10+ designer workers here.

You just give us one picture or draft, our designers who will make come true.

And very important that we make your brand valued and much stronger after our products.

Our QC DEP will do 3 times inspection.

FABRIC & DYE color inspection during pre-production inspection.

Final inspection.

Such a careful inspection system keeps our quality assured !

We have a stronger and professional team to push and control shipment time, there are QC

System, Shipping DEP, Merchandiser DEP, Sourcing DEP and so on!